In a transformative leap for India’s aerospace and defense sector, Tata Advanced Systems Limited (TASL) has solidified its position as a global contender through landmark agreements with Dassault Aviation and Airbus. These deals, centered on the production of Rafale fighter jet fuselages and the C295 transport aircraft, mark a pivotal moment in India’s journey toward self-reliance in high-end aerospace manufacturing. With production facilities set to be established in Hyderabad and Vadodara, TASL is not only bolstering India’s defense capabilities but also positioning the nation as a critical hub in the global aerospace supply chain.

Rafale Fuselage Production: A Milestone in Hyderabad

On June 5, 2025, Dassault Aviation, the French aerospace giant behind the Rafale fighter jet, announced a historic partnership with TASL to manufacture complete Rafale fuselages in India—the first such facility outside France. This collaboration, formalized through four Production Transfer Agreements, will see TASL establish a state-of-the-art production plant in Hyderabad. The facility will produce key sections of the Rafale fuselage, including the front, central, rear, and lateral shells, with production slated to commence in FY2028. The plant aims to deliver up to two fuselages per month, catering to both domestic and global demands.

“This partnership marks a significant step in India’s aerospace journey,” said Sukaran Singh, CEO and Managing Director of TASL. “The production of complete Rafale fuselages in India is a testament to the deepening trust between our companies and reflects India’s progress in building a modern aerospace manufacturing ecosystem.” Eric Trappier, Chairman and CEO of Dassault Aviation, echoed this sentiment, emphasizing that the Hyderabad facility will contribute to the successful ramp-up of Rafale production while meeting stringent quality and competitiveness standards.

The Hyderabad plant represents a vital investment in India’s aerospace infrastructure, aligning with the government’s “Make in India” and AtmaNirbhar Bharat (Self-Reliant India) initiatives. By producing high-precision components domestically, India is reducing its reliance on foreign suppliers and enhancing its position in the global aerospace supply chain. The facility is expected to create hundreds of skilled jobs, foster technology transfer, and drive innovation in advanced manufacturing techniques.

C295 Manufacturing: Strengthening India’s Defense Logistics

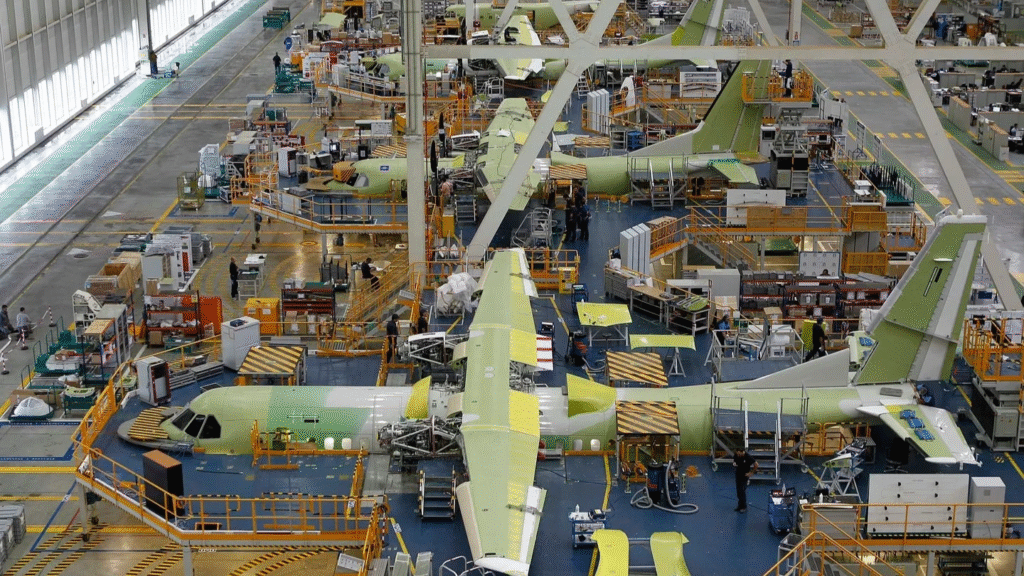

In parallel, TASL’s collaboration with Airbus to establish a Final Assembly Line (FAL) for the C295 transport aircraft in Vadodara is another feather in its cap. This project, part of a $2.5 billion deal signed in 2021, involves the production of 56 C295 aircraft for the Indian Air Force, with 40 to be assembled in India. The Vadodara facility, inaugurated in October 2024, is a joint venture between TASL and Airbus, marking India’s first private-sector military aircraft manufacturing unit.

The C295, a versatile medium tactical transport aircraft, is designed to replace the Indian Air Force’s aging Avro fleet. With a payload capacity of 5-10 tonnes, it is well-suited for a range of missions, including troop transport, logistics support, and disaster relief. The Vadodara plant is expected to deliver its first Indian-made C295 by 2026, with the remaining aircraft to be produced at a steady pace over the next decade. This initiative not only strengthens India’s defense logistics but also positions TASL as a key player in Airbus’s global supply chain.

The C295 program includes significant technology transfer and indigenization efforts. Over 13,000 components of the aircraft will be manufactured locally, with TASL overseeing the assembly, testing, and delivery processes. This has already spurred the development of a robust ecosystem of local suppliers, including small and medium enterprises, further amplifying India’s aerospace manufacturing capabilities.

Helicopter Assembly Line: Expanding the Portfolio

Adding to its growing portfolio, TASL is partnering with Airbus to establish India’s first private-sector helicopter Final Assembly Line in Kolar, Karnataka. Announced in May 2025, this facility will produce the Airbus H125, a single-engine helicopter widely used for civil and parapublic missions such as emergency medical services, law enforcement, and tourism. The Kolar plant, located in the Vemagal Industrial Area near Bengaluru, will initially produce 10 helicopters annually, with plans to scale up based on regional demand projections of 500 H125-class helicopters over the next two decades.

Karnataka’s established aerospace ecosystem, skilled workforce, and supportive state policies made it an ideal location for this venture. The facility will encompass manufacturing, final assembly, and maintenance, repair, and overhaul (MRO) operations, further diversifying TASL’s capabilities. This project underscores India’s ambition to become a hub for rotorcraft manufacturing, complementing its fixed-wing aircraft production efforts.

Strategic Implications for India’s Aerospace Industry

The Rafale and C295 deals, combined with the H125 helicopter project, position TASL at the forefront of India’s aerospace revolution. These initiatives have far-reaching implications for the country’s defense and economic landscape:

- Self-Reliance in Defense Manufacturing: By producing critical components and entire aircraft domestically, India is reducing its dependence on foreign imports, a key objective of the AtmaNirbhar Bharat initiative. The technology transfer embedded in these agreements empowers Indian industries to master complex manufacturing processes, paving the way for future indigenous projects like the Advanced Medium Combat Aircraft (AMCA).

- Global Supply Chain Integration: The Hyderabad and Vadodara facilities integrate India into the global aerospace supply chain, enabling TASL to supply high-quality components to Dassault and Airbus for their worldwide operations. This enhances India’s reputation as a reliable partner in high-tech manufacturing.

- Economic and Employment Growth: These projects are expected to generate thousands of direct and indirect jobs, from highly skilled engineers to technicians and support staff. The ripple effect will stimulate local economies, particularly in Telangana, Gujarat, and Karnataka, while fostering a network of ancillary industries.

- Strategic Defense Preparedness: The Rafale and C295 programs bolster India’s military capabilities at a time of heightened regional tensions.

Last Updated on: Tuesday, July 1, 2025 10:10 pm by Aagya | Published by: Aagya on Thursday, June 5, 2025 5:11 pm | News Categories: India News

Leave a Reply